- Home Page

- Company Profile

-

Our Products

- Reactive Dyes Intermediates

- Thio Salicylic Acid

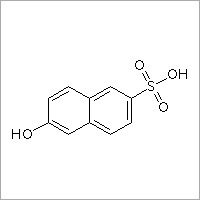

- 6-hydroxynaphthalene-2-sulfonic acid

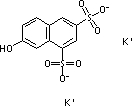

- K Acid Empirical Formula : C10H9O9NS3

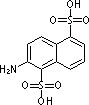

- Aniline 2 : 5 Disulfonic Acid

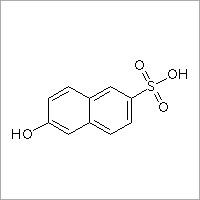

- Schaeffer Acid

- Aniline 25- Disulphonic Acid

- Amido G Acid

- Schaeffer's Acid

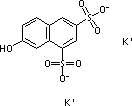

- G Salt

- Gamma Acid

- Amino Iso G. Acid

- Aniline 2:5 Disulphonic Acid

- Anthranilic Acid

- B-Naphthyl Amine -3 : 6 : 8 Trisulphonic Acid

- 5-Sulfo Anthranilic Acid

- Phthalimide

- N-Methyl J-Acid

- Hydroxynaphthalene Sulfonic Acid

- Sulfo Tobias Acid

- J Acid

- R Salt

- 4 Nitro Phthalimide

- N-Methyl Anthranilic Acid

- Potassium Phthalimide

- G Salt Chemical Compound

- 4- Nitrophthalimide

- Phthalimide Chemical Compound

- R- Salt Chemical Compound

- K Acid

- Chemical Compound

- 6-8 Trisulphonic Acid Chemical Compound

- Amido G Acid Chemical Compound

- Aniline 2-5 Disulfonic Acid

- Pure Schaeffer Acid Chemical Compound C10H8O7S2

- 4 Nitro Phthalimide Chemical Compound

- 6- Hydroxynaphthalene-2- Sulfonic Acid

- B-Naphthyl Amine-3-6-8 Trisulphonic Acid

- Reactive Dyes Intermediates

- Contact Us

G Salt

Price 195 INR/ Kilograms

MOQ : 50 Kilograms

G Salt Specification

- Melting Point

- 300C (decomposes)

- Refractive Rate

- Not Available

- Water Resistant

- Yes

- Density

- 1.68 Gram per cubic centimeter(g/cm3)

- Shelf Life

- 2 Years

- Rubbing Resistance

- Moderate

- Taste

- Characteristic

- Moisture (%)

- <1%

- Shape

- Powder

- Resistance

- Light and Heat Resistant

- Solubility

- Soluble in Water

- Smell

- Odorless

- Solvent Color

- Yellow

- Chemical Name

- Tartrazine

- Type

- Synthetic Organic Dye

- Usage

- Industrial, Laboratory Use

- Purity(%)

- 99%

- Application

- Textile, Paper, Ink, and Food Industry

- Appearance

- Yellowish Powder

- Physical Form

- Solid

- Grade

- Industrial Grade

G Salt Trade Information

- Minimum Order Quantity

- 50 Kilograms

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 2 Days

About G Salt

G Salt

CAS NO. : 842-18-2

- M.W. : 304

- Empirical Formula : C10H8O7S2

- Synonyms

- 2 - Naphthol 6, 8 -Disulphonic Acid.

- 2 - Hydroxynaphthalene-6, 8 - Disulphonic Acid

- Form Supplied : Wet Cake

- Basis For Sale : On Real Content, M.W. 304

- Packing : H. D. P. E. Bags with inside polythene liner.

- Description : Dull Whit To Light Coloured Moist Meterial.

- Nature of Material : Dipotassium Salt.

- Strength : @ 65 To 70% (Wet Cake)

- Solubility : Soluble In Water, Dilute Alkali.

Use : Intermediate For Dye stuffs, Food Colours.

Consistent Quality and Purity

Each batch of G Salt is rigorously evaluated to ensure a consistent 99% purity and standardized dye strength. This process guarantees that the product meets strict industrial-grade standards and delivers reliable results for every application, from textiles to inks and food processing.

Optimal Storage and Handling

G Salt is packaged in secure 25 kg bags, designed for safe transportation and storage. It should be stored in cool, dry conditions to uphold its stability and maintain its shelf life of up to two years. Following these guidelines helps to preserve its high-quality properties and application efficiency.

Versatile Industrial Applications

Targeting sectors such as textile, paper, ink, and food industry, this synthetic organic dye exhibits excellent solubility and color fastness. Its strong water, light, and heat resistance make it suitable for processes that demand consistent pigment performance and stability under diverse industrial conditions.

FAQs of G Salt:

Q: How should G Salt be stored for optimal stability?

A: G Salt maintains its stability best when stored in a cool, dry location and kept in its original packaging. Avoid exposure to moisture and direct sunlight to ensure its quality remains intact throughout its two-year shelf life.Q: What industries commonly utilize G Salt and why?

A: G Salt is primarily used in the textile, paper, ink, and food industries due to its excellent solubility, bright yellow color, and standardized dye strength. The dyes resistance to heat, light, and water ensures lasting color and reliability in various manufacturing processes.Q: When should G Salt be used in industrial processes?

A: G Salt should be added during manufacturing stages where a vibrant and stable yellow color is required, particularly in aqueous solutions. It is especially beneficial at points where its color fastness and solubility contribute to the consistency and quality of the final product.Q: Where is G Salt manufactured and distributed?

A: G Salt is produced, exported, imported, and distributed by leading companies across India, serving a range of clients in industrial and laboratory sectors. Suppliers ensure quality, compliance, and timely delivery to manufacturers nationwide.Q: What is the process of applying G Salt in textile dyeing?

A: In textile dyeing, G Salt is dissolved in water to form a uniform solution, which is then applied to fabrics during the coloration phase. Adequate solubility and standardized strength allow for controlled, consistent dye penetration and vibrant color output.Q: What are the main benefits of using G Salt in manufacturing?

A: Key advantages include its 99% purity, robust stability in various conditions, intense yellow color, strong resistance to fading and water exposure, and suitability for large-scale applications. These features enable manufacturers to achieve reliable results with minimal waste or reprocessing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Reactive Dyes Intermediates Category

G Salt Chemical Compound

Price 195 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Physical Form : Powder

Appearance : White to Offwhite Powder

Usage : Other, Industrial

Water Resistant : Yes

6-hydroxynaphthalene-2-sulfonic acid

Price 225.00 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Physical Form : Solid

Appearance : Light Yellow to Brownish Powder

Usage : Other, Organic Synthesis, Dye Manufacturing

Water Resistant : Yes

Sulfo Tobias Acid

Physical Form : Powder

Appearance : Light brown powder

Usage : Other, Industrial

Water Resistant : Yes

Hydroxynaphthalene Sulfonic Acid

Physical Form : Solid

Appearance : Reddish Brown Powder

Usage : Other, Used in dye and pigment synthesis

Water Resistant : Yes

Our Associate Concern

Everest Intermediates

Plot No. 706, 707 & 709, Road No. 7

GIDC Estate, Sachin, Dist. Surat-394230

Phone: 91-261-2453000/2433303

Everest Intermediates

Plot No. 706, 707 & 709, Road No. 7

GIDC Estate, Sachin, Dist. Surat-394230

Phone: 91-261-2453000/2433303

Send Inquiry

Send Inquiry