- Home Page

- Company Profile

-

Our Products

- Reactive Dyes Intermediates

- Thio Salicylic Acid

- 6-hydroxynaphthalene-2-sulfonic acid

- K Acid Empirical Formula : C10H9O9NS3

- Aniline 2 : 5 Disulfonic Acid

- Schaeffer Acid

- Aniline 25- Disulphonic Acid

- Amido G Acid

- Schaeffer's Acid

- G Salt

- Gamma Acid

- Amino Iso G. Acid

- Aniline 2:5 Disulphonic Acid

- Anthranilic Acid

- B-Naphthyl Amine -3 : 6 : 8 Trisulphonic Acid

- 5-Sulfo Anthranilic Acid

- Phthalimide

- N-Methyl J-Acid

- Hydroxynaphthalene Sulfonic Acid

- Sulfo Tobias Acid

- J Acid

- R Salt

- 4 Nitro Phthalimide

- N-Methyl Anthranilic Acid

- Potassium Phthalimide

- G Salt Chemical Compound

- 4- Nitrophthalimide

- Phthalimide Chemical Compound

- R- Salt Chemical Compound

- K Acid

- Chemical Compound

- 6-8 Trisulphonic Acid Chemical Compound

- Amido G Acid Chemical Compound

- Aniline 2-5 Disulfonic Acid

- Pure Schaeffer Acid Chemical Compound C10H8O7S2

- 4 Nitro Phthalimide Chemical Compound

- 6- Hydroxynaphthalene-2- Sulfonic Acid

- B-Naphthyl Amine-3-6-8 Trisulphonic Acid

- Reactive Dyes Intermediates

- Contact Us

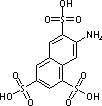

K Acid Empirical Formula : C10H9O9NS3

K Acid Empirical Formula : C10H9O9NS3 Specification

- Density

- 1.88 Gram per cubic centimeter(g/cm3)

- Melting Point

- >300C (Decomposes)

- Resistance

- Stable under normal conditions

- Shelf Life

- 2 Years

- Poisonous

- Yes

- Solvent Color

- Colourless to Pale

- Water Resistant

- Yes

- Shape

- Powder

- Ph Level

- ~2 (1% Solution)

- Taste

- Odourless

- Refractive Rate

- Not Available

- Moisture (%)

- Max 1.0%

- Molecular Formula

- C10H9O9NS3

- Solubility

- Soluble in Water

- Smell

- Odourless

- Type

- Acid

- Usage

- Dye Intermediate

- Purity(%)

- 99%

- Application

- Manufacture of Dyes, Pigments, and Optical Brightening Agents

- Appearance

- Grey to Off White Powder

- Physical Form

- Solid

- Grade

- Industrial Grade

About K Acid Empirical Formula : C10H9O9NS3

K Acid (CAS NO. : 118-03-6) Details:- M.W. : 383

- Empirical Formula : C10H9O9NS3

- Synonyms : 2-Naphthylamine-3 : 6 : 8 Trisulphonic Acid Or B-Naphthyl Amine-3 : 6 : 8 Trisulphonic Acid

- Form Supplied : Moist

- Basis For Sale : On Real Content, M.W. 383

- Packing : H. D. P. E. Bags with inside polythene liner

- Description : Pale Yellow (Powder Form)

- Nature of Material : Free Sulphonic Acid

- Strength (by Nitrite Value) : @ 65% To 70% (Wet Cake)

- Solubility : Soluble In Water, Dilute alkali

- Use : Intermediate for reactive dye stuffs.

A Trusted Dye Intermediate

K Acid is renowned for its role in the synthesis of dyes and pigments, offering manufacturers a reliable and high-purity component for creating vibrant, high-quality colorants. Its excellent solubility in water and stable behavior in industrial settings make it ideal for large-scale applications. The consistent physical and chemical properties contribute significantly to product quality and process efficiency.

Versatility in Applications

Beyond dye manufacturing, K Acid is also employed in producing optical brightening agents. These applications leverage its chemical structure to enhance brightness and whiteness in textiles and papers. Its industrial-grade specification ensures compatibility in a variety of advanced chemical processes, underpinning its popularity with exporters, distributors, and manufacturers globally.

FAQs of K Acid Empirical Formula : C10H9O9NS3:

Q: How is K Acid typically used in the manufacturing sector?

A: K Acid is primarily utilized as an intermediate in the synthesis of dyes, pigments, and optical brightening agents. Its solubility in water and consistent purity enable efficient processing and integration into various chemical formulations.Q: What are the storage recommendations for K Acid to ensure product stability?

A: K Acid should be stored in a cool, dry, and well-ventilated area, away from incompatible materials and moisture to maintain its quality. Keep the container tightly sealed and follow standard safety protocols for handling industrial chemicals.Q: When should K Acid be used in the dye manufacturing process?

A: K Acid is introduced during the intermediate phase of dye synthesis, where it acts as a precursor to various dyes and pigments. Manufacturers integrate it into the process post-primary mixing to achieve the desired chemical transformations.Q: Where is K Acid commonly applied outside the dye industry?

A: Beyond dye manufacturing, K Acid is also used in the production of optical brightening agents that improve the brightness of textiles, paper, and detergents, making it essential for various industrial applications.Q: What safety measures should be taken when handling K Acid?

A: Due to its acidic and poisonous nature, handlers must use protective equipment such as gloves, goggles, and masks. Adequate ventilation and adherence to safety guidelines are crucial to prevent exposure and accidental ingestion or inhalation.Q: What are the main benefits of using K Acid with 99% purity in industrial processes?

A: High-purity K Acid ensures consistent results, enhanced product performance, and reduced impurities in end products, particularly in high-quality dye and pigment manufacturing.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Reactive Dyes Intermediates Category

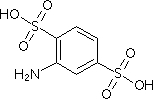

Aniline 2:5 Disulphonic Acid

Moisture (%) : <1%

Molecular Formula : C6H6O6S2

Solubility : Soluble in water

Type : Other, Dye Intermediate

Smell : Other, Slight aromatic

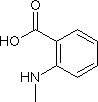

Phthalimide

Minimum Order Quantity : 100 Kilograms

Moisture (%) : <0.5%

Molecular Formula : C8H5NO2

Solubility : Slightly soluble in water, soluble in hot ethanol

Type : Other, Chemical Compound

Smell : Other, Odorless

N-Methyl J-Acid

Moisture (%) : 0.5%

Molecular Formula : C11H11NO6S

Solubility : Soluble in water

Type : Other, Acid Dye Intermediate

Smell : Other, Odorless

Aniline 25- Disulphonic Acid

Minimum Order Quantity : 25 Liters

Moisture (%) : <1%

Molecular Formula : C6H6N2O6S2

Solubility : Soluble in water

Type : Other, Acid

Smell : Other, Odorless

Our Associate Concern

Everest Intermediates

Plot No. 706, 707 & 709, Road No. 7

GIDC Estate, Sachin, Dist. Surat-394230

Phone: 91-261-2453000/2433303

Everest Intermediates

Plot No. 706, 707 & 709, Road No. 7

GIDC Estate, Sachin, Dist. Surat-394230

Phone: 91-261-2453000/2433303

Send Inquiry

Send Inquiry